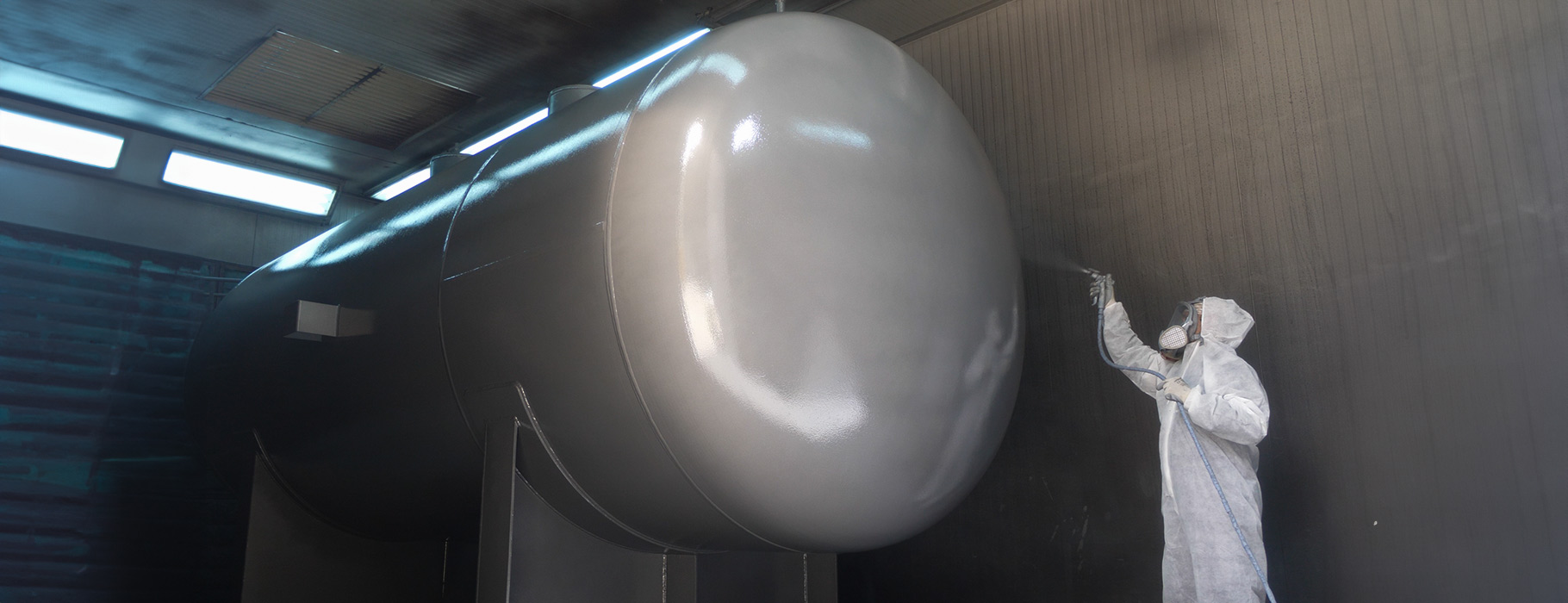

Surface Preparation

Remove contaminants that compromise strength

Steel doesn’t come ready. It arrives with scale, rust, residue — all of which interfere with how your systems perform. Surface preparation is where we strip it back, clean it up, and get it ready to last.