Heat Transfer Solutions

Process stability starts with thermal control

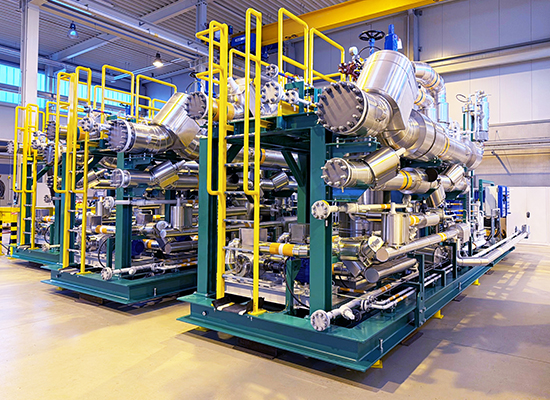

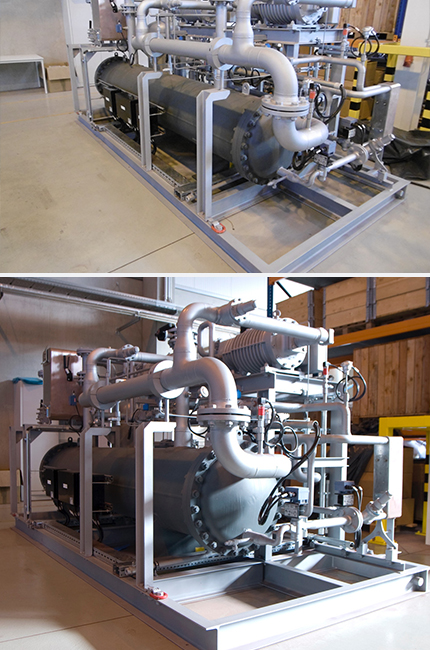

From concept to commissioning, our heat transfer solutions are integrated into the process with full fabrication, assembly, and documentation under one roof.

From concept to commissioning, our heat transfer solutions are integrated into the process with full fabrication, assembly, and documentation under one roof.

For high-pressure, high-temperature media – robust design with cleanability access

For process loops, thermal oil lines, and heat-sensitive product flows

Packaged units with pumps, control valves, and thermal sensors – all pre-wired and tested

We fabricate heat transfer systems with practical realities in mind — lifting access, outdoor mounting, corrosion exposure, and local maintenance skill sets.

FATs are conducted with your team or third-party inspectors on site.