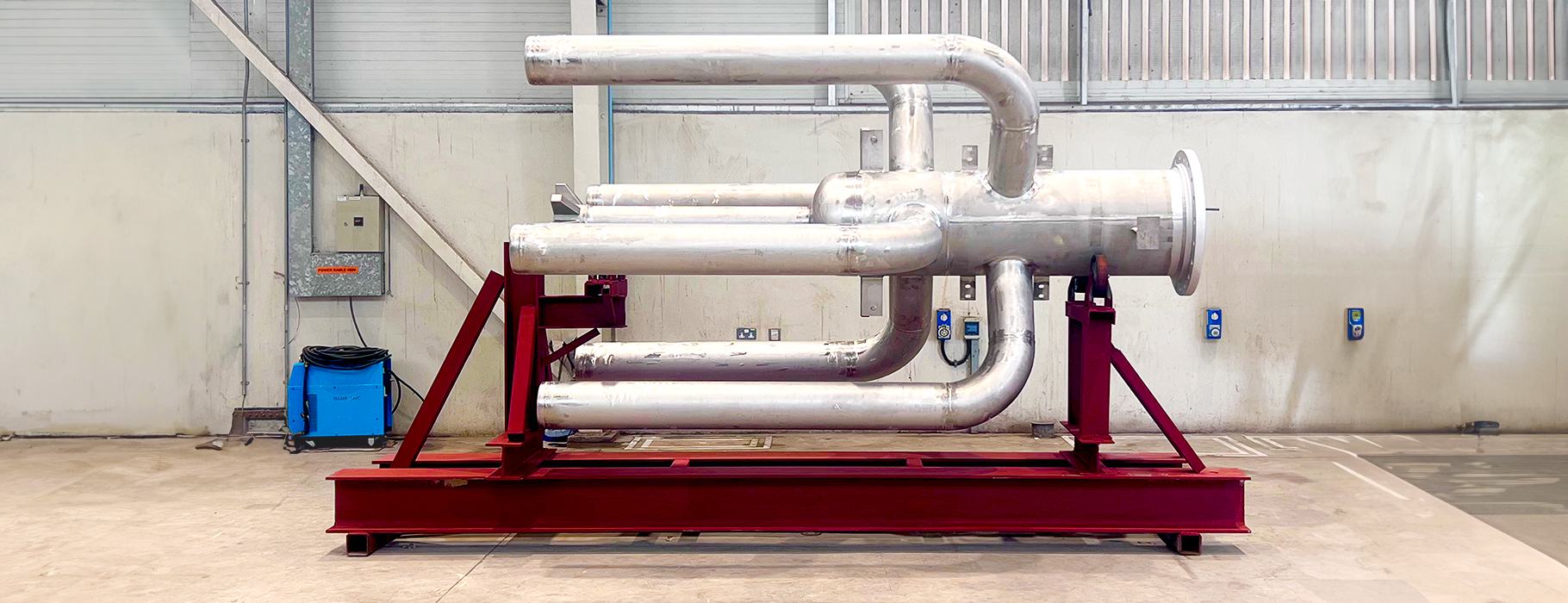

Flare System Components

Manufactured to OEM Specifications for Flare System Integration

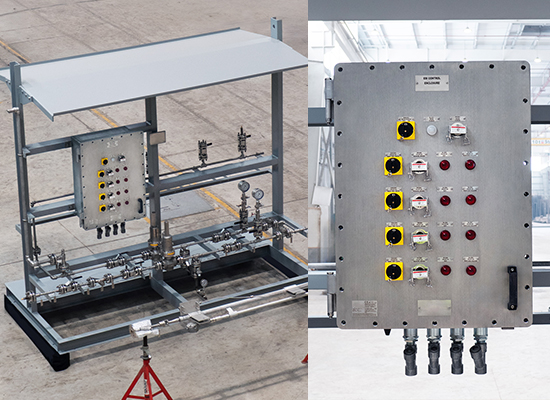

We supply structural and piping components that form the core of flare systems—built for integration by leading OEMs. From flare tips and utility piping to support frames, every unit is fabricated to tight tolerances, with materials and welds qualified for high-heat, high-vibration, and corrosive service environments.