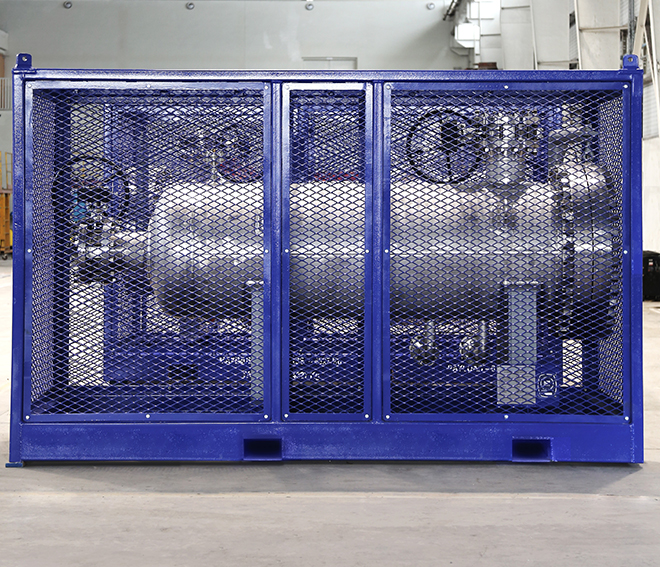

Pressure Vessels

Built for reliability, tested under load.

Pressure vessels from PSI serve as integral components across energy and industrial systems. Designed and fabricated under certified quality systems—including ASME Section VIII Division 1 (‘U’ Stamp) and PED—they are engineered for reliability from first weld to final inspection.